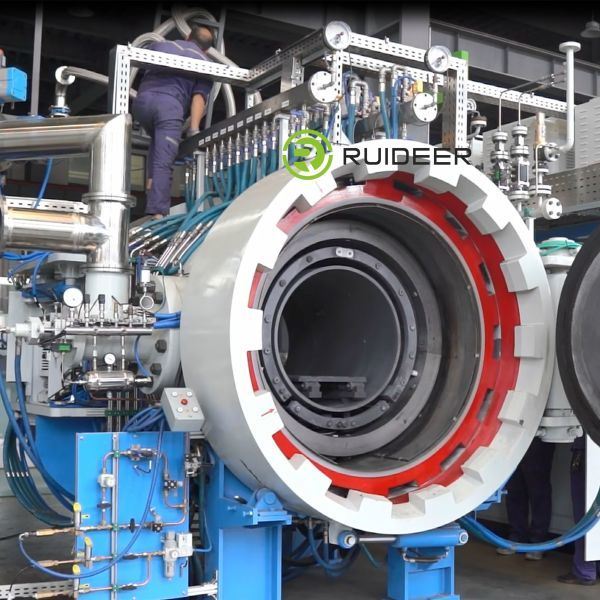

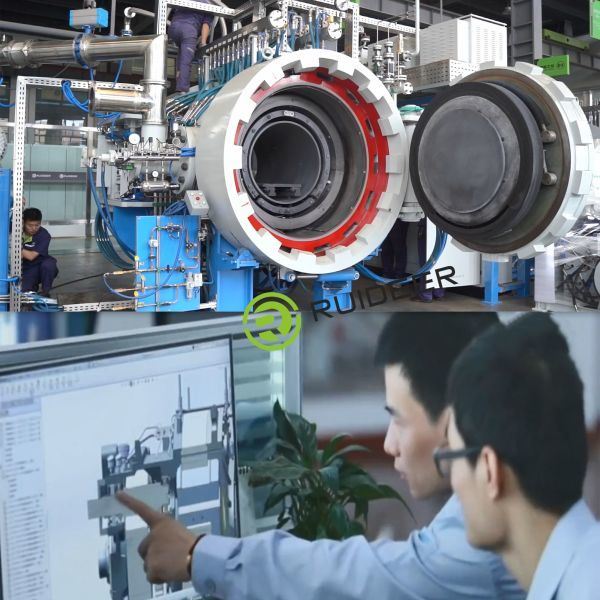

Furnace Description:

The Sintering Furnace Accessories product is designed to enhance the functionality and efficiency of your sintering furnace. With top-notch features and high-quality construction, these accessories are essential for optimizing your sintering process.

One of the standout attributes of these accessories is the insulation material. Made from high-grade Mullite, these accessories provide excellent insulation properties, ensuring that your furnace maintains optimal operating temperatures and minimizes heat loss.

Another key feature of these accessories is the cooling system. Equipped with an efficient water cooling system, these accessories help regulate the temperature inside the furnace, preventing overheating and ensuring consistent sintering processes.

When it comes to the atmosphere used in the sintering process, these accessories offer versatility. Whether you prefer to operate in air or inert gas environments, these accessories can accommodate your specific requirements, providing the flexibility you need for diverse sintering applications.

The weight of these accessories is customizable, allowing you to adjust the load capacity based on your furnace's specifications and the materials being processed. This customization feature ensures that your sintering furnace operates smoothly and efficiently, delivering optimal results with each cycle.

For power supply compatibility, these accessories support both 220V and 380V inputs, making them suitable for a wide range of sintering furnace setups. With this flexibility, you can easily integrate these accessories into your existing system without the need for extensive modifications.

Among the notable components included in these accessories are the Siemens Module, Connecting Hook Plate, and Pneumatic Ball Valve. The Siemens Module ensures reliable and precise control over the furnace's operations, while the Connecting Hook Plate facilitates secure connections between various furnace components. Additionally, the Pneumatic Ball Valve enables efficient regulation of gas flow, enhancing the overall performance of the sintering process.

Overall, the Sintering Furnace Accessories product offers a comprehensive solution for enhancing the functionality and performance of your sintering furnace. With superior insulation, efficient cooling, versatile atmosphere options, customizable weight capacity, and compatibility with different power supplies, these accessories are designed to optimize your sintering operations and deliver consistent, high-quality results.

Graphite Parts Features:

- High - temperature Resistance and Stability: The heating assembly of Ruideer's vacuum pressure furnace usually adopts high - quality heating elements such as graphite heating elements. These heating elements have excellent high - temperature resistance, which can ensure stable operation of the heating assembly at high temperatures. For example, in some of its vacuum sintering furnaces, the maximum working temperature can reach 1800°C, and the heating elements can still maintain good performance at this temperature, providing reliable heat source support for the furnace.

- Good Temperature Uniformity: The heating assembly is equipped with a reasonable temperature - control system. The equipment has 2 to 6 independent temperature - control zones. This design enables the furnace to have excellent temperature uniformity even in the largest - sized models, with the temperature uniformity being ≤±5°C. This ensures that the materials in the furnace can be heated evenly during the processing, which is crucial for improving the quality and consistency of products.

- Long Service Life of Heating Elements: Taking the RYL1400 vacuum hot - pressing sintering furnace as an example, it uses high - quality SGL graphite rods as heating elements. These rods have a long service life, which can reduce the frequency of heating - element replacement, lower the maintenance cost of the equipment, and improve the production efficiency.

- Efficient Heating and Energy - Saving: Some of Ruideer's vacuum pressure furnaces use a high - strength graphite plate heating system. This kind of heating assembly has a large heating area, which can make the furnace heat up quickly. At the same time, combined with a reasonable insulation structure, such as using CFC (carbon - fiber - reinforced carbon) as the insulation material, it can reduce heat loss and achieve the effect of energy - saving. For example, in a certain model of the furnace, this design can save about 200 degrees of electricity per day.

- Customizable Design: According to customer needs, Ruideer can carry out customized design and production of the heating assembly. Whether it is a laboratory - scale (12L) or a production - scale (up to 1000L) furnace type, different pressure and temperature requirements can be met, which can meet the diverse process needs of different customers.

Technical Parameters:

| Bulk Density (g/cm³) |

≥1.85 |

| Ash Content (ppm) |

≤500 |

| Shore Hardness |

≥45 |

| Resistivity (μΩ・m) |

≤12 |

| Flexural Strength (MPa) |

≥40 |

| Compressive Strength (MPa) |

≥70 |

| Coefficient of Thermal Expansion (mm/°C) |

≤4.4×10⁻⁶ |

Applications:

The graphite heating assembly of Ruideer's vacuum pressure furnace is widely applied in industrial scenarios requiring high-temperature, vacuum, and pressure-controlled environments, with its core applications focused on material sintering and heat treatment processes. Below is a detailed breakdown of its key application fields:

It serves as the core heating component for sintering hard alloy products such as cemented carbide inserts, geological drilling bits, and cutting tools. The high-purity graphite material (with ash content ≤500 ppm) prevents impurity contamination of the alloy during the sintering process. Meanwhile, its excellent temperature uniformity (≤±5°C) ensures consistent density and hardness of the alloy, avoiding defects like internal cracks caused by uneven heating.

It is suitable for the sintering of advanced ceramic materials, including alumina ceramics, zirconia ceramics, and silicon carbide ceramics. The graphite heating assembly can stably operate at high temperatures up to 1800°C, meeting the high-temperature requirements of ceramic sintering. Its low thermal expansion coefficient (≤4.4×10⁻⁶ mm/℃) ensures minimal deformation under temperature cycles, maintaining the precision of ceramic workpieces.

In the powder metallurgy industry, it is used for the sintering of metal powder compacts, such as iron-based, copper-based, and stainless-steel powder metallurgy parts. The efficient heating performance of the assembly (paired with a carbon-fiber insulation structure) enables rapid and uniform heating of the furnace chamber, shortening the sintering cycle. Additionally, its high compressive strength (≥70 MPa) allows it to withstand the pressure environment of pressure-assisted sintering, improving the density of powder metallurgy products.

It is applied in the heat treatment and sintering of rare metals (tungsten, molybdenum, titanium) and their composite materials. The high-temperature resistance of graphite (stable at 1800°C) matches the high melting points of rare metals. The low-resistivity design (≤12 μΩ·m) of the heating assembly ensures efficient energy conversion, reducing energy consumption during long-term high-temperature operations—critical for cost control in rare metal processing.

For research institutions and enterprises engaged in new material R&D, the customizable design of the graphite heating assembly (adaptable to 12L–1000L furnace chambers) supports small-batch pilot tests. Its precise temperature control and low impurity release help researchers obtain accurate data on material sintering behavior, accelerating the development of new materials like high-performance ceramics and composite powders.

Customization:

Product Customization Services for the Sintering Furnace Accessories:

Brand Name: RUIDEER

Place of Origin: China

Support and Services:

The Product Technical Support and Services for the Sintering Furnace Accessories product include:

- Installation guidance and support for setting up the sintering furnace accessories.

- Troubleshooting assistance for any technical issues that may arise during operation.

- Training programs for users to ensure proper use and maintenance of the accessories.

- Regular maintenance services to keep the accessories in optimal working condition.

Packing and Shipping:

Product: Sintering Furnace Accessories

Description: High-quality accessories compatible with sintering furnaces for various applications.

Packaging:

- All accessories are carefully packaged in individual protective sleeves to prevent any damage during transit.

- Packaged in a sturdy cardboard box with cushioning material to ensure safe delivery.

Shipping:

- Shipping method: Standard ground shipping via reputable carriers.

- Estimated delivery time: 3-5 business days within the contiguous United States.

- International shipping available with longer delivery times based on location.

FAQ:

1. Q: What is the brand name of these sintering furnace accessories?

A: The brand name is RUIDEER.

2. Q: Where are these sintering furnace accessories manufactured?

A: These accessories are manufactured in China.

3. Q: What are the model numbers available for these sintering furnace accessories?

A: The available model numbers are 224, 4412, 5512, and 5518.

4. Q: Are these accessories compatible with all types of sintering furnaces?

A: These accessories are designed to be compatible with a wide range of sintering furnaces, but it's recommended to check the compatibility with your specific furnace model.

5. Q: Do these accessories come with a warranty?

A: For warranty-related information, please refer to the warranty policy provided by the manufacturer.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!