Product Description:

The Sintering Furnace Accessories product offered is designed to enhance the functionality and performance of your sintering furnace. With a reliable warranty of 1 year, you can trust in the quality and durability of these accessories.

The cooling system of these accessories is equipped with water cooling technology, ensuring efficient heat dissipation and temperature control during the sintering process. This feature helps in maintaining optimal working conditions and prolonging the lifespan of your sintering furnace.

Operating in air or inert gas atmospheres, these accessories provide flexibility in sintering applications. The ability to work in different atmospheres allows for versatility in material processing and ensures precise control over the sintering environment.

Compatible with power supplies of 220V or 380V, these accessories offer versatility in power input options, making them suitable for a wide range of sintering furnace setups. This adaptability ensures seamless integration with existing equipment and enables efficient operation.

Constructed from high-quality ceramic material, these accessories are durable and resistant to high temperatures, ensuring long-lasting performance in demanding sintering applications. The ceramic construction also provides thermal stability and uniform heat distribution, contributing to consistent sintering results.

Key accessories included in this product offering are the Double-core Tungsten-Rhenium Thermocouple and Vacuum pump unit. The Double-core Tungsten-Rhenium Thermocouple enables accurate temperature measurement and control, ensuring precise sintering conditions for optimal material processing. The Vacuum pump unit facilitates the creation of vacuum environments within the sintering furnace, essential for certain sintering processes and material treatments.

Enhance the capabilities of your sintering furnace with these premium accessories, designed to optimize performance, provide precise control, and support a wide range of sintering applications. Invest in quality accessories that deliver reliability, efficiency, and consistent results for your sintering operations.

Features:

- Product Name: Sintering Furnace

- Power Supply: 220V/380V

- Charging Weight: 50-1500kg

- Color: Blue/green

- Warranty: 1 Year

Technical Parameters:

| Color |

Blue/green |

| Cooling System |

Water Cooling |

| Weight |

Customizable |

| Insulation Material |

Mullite |

| Warranty |

1 Year |

| Atmosphere |

Air/Inert Gas |

| Max. Heating Rate |

20°C/min |

| Power Supply |

220V/380V |

| Control System |

PID Temperature Controller |

| Insulation Thickness |

50mm |

Applications:

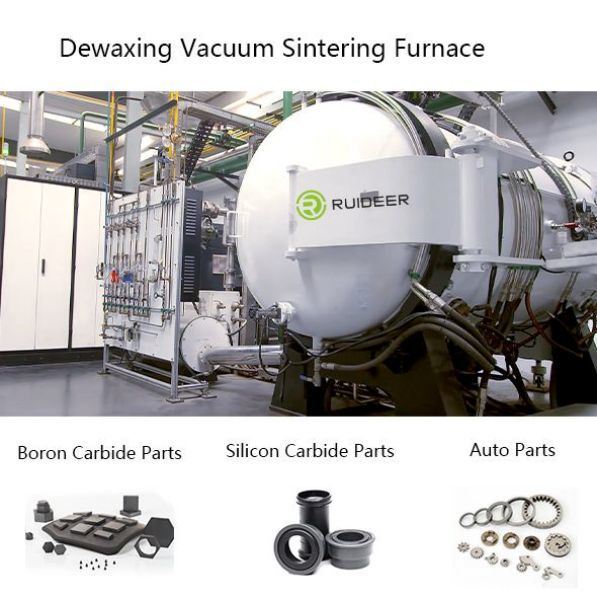

RUIDEER Sintering Furnace Accessories are designed for various product application occasions and scenarios. These accessories, including vacuum pump units, slide valve pumps, and armored thermocouples, cater to a wide range of sintering furnace models such as 224, 4412, 5512, and 5518.

Manufactured in China, these accessories are known for their high-quality performance and reliability. The power supply options of 220V or 380V make them versatile for different industrial settings.

The insulation material used in these accessories is Mullite, ensuring efficient heat retention and distribution. With a maximum heating rate of 20°C/min, these accessories are suitable for demanding sintering processes that require precise temperature control.

Equipped with a PID Temperature Controller as part of the control system, users can easily monitor and adjust the furnace parameters for optimized sintering results. The blue and green color options add a touch of vibrancy to the accessories, making them visually appealing in industrial settings.

Whether it's for research laboratories, production facilities, or educational institutions, RUIDEER Sintering Furnace Accessories offer a reliable solution for various sintering applications. The vacuum pump units ensure proper evacuation of the furnace chamber, while the slide valve pumps facilitate gas flow control during the sintering process.

Additionally, the armored thermocouples provide accurate temperature measurements, essential for maintaining the desired sintering conditions. These accessories are designed to enhance the overall performance and efficiency of sintering furnaces, making them essential components for achieving high-quality sintered products.

Customization:

Product Customization Services for the Sintering Furnace Accessories:

Brand Name: RUIDEER

Model Number: 224/4412/5512/5518

Place of Origin: China

Insulation Material: Mullite

Warranty: 1 Year

Color: Blue/green

Weight: Customizable

Product attributes include Heat Insulation Door, Double-core Tungsten-Rhenium Thermocouple, Roots pump

Support and Services:

Our Product Technical Support and Services for the Sintering Furnace Accessories include:

- Installation guidance and support for proper setup

- Troubleshooting assistance for any technical issues

- Maintenance recommendations to ensure optimal performance

- Product training sessions for operators and maintenance staff

- Access to product manuals and documentation for reference

Packing and Shipping:

Product Packaging and Shipping:

Our Sintering Furnace Accessories are carefully packaged to ensure safe delivery to our customers. Each accessory is securely wrapped and placed in a sturdy box to prevent damage during transit.

For shipping, we use reliable carriers to deliver your order promptly. You can track your shipment using the provided tracking number to know the status of your package.

FAQ:

Q: What is the brand name of the Sintering Furnace Accessories?

A: The brand name is RUIDEER.

Q: What are the available model numbers for the Sintering Furnace Accessories?

A: The available model numbers are 224, 4412, 5512, and 5518.

Q: Where is the Sintering Furnace Accessories manufactured?

A: The accessories are manufactured in China.

Q: Are these accessories compatible with specific sintering furnace models?

A: Yes, these accessories are designed to be compatible with specific sintering furnace models. Please refer to the product specifications for compatibility details.

Q: Can these accessories be used for both residential and commercial sintering applications?

A: Yes, these accessories are suitable for both residential and commercial sintering applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!