PLC Controlled Pressure-Sintering Furnace With Graphite Heating Element For Sintering

Product Description:

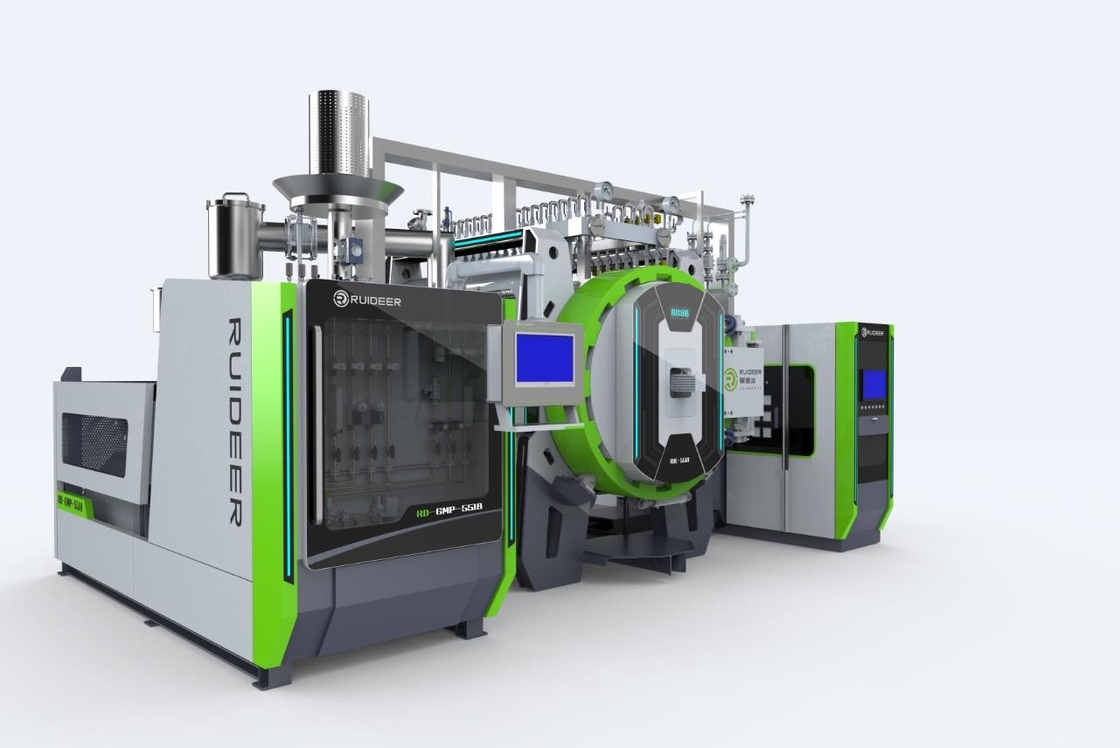

Sinter HIP Furnace

Product Overview

- Product Name: Sinter HIP Furnace

- Product Type: High-Pressure Sintering Furnace, High-Temperature Furnace, High-Pressure Heat Treatment Furnace

- Vacuum Level: 1Pa

- Temperature Range: 0-1700℃

- Material: Stainless Steel, Carbon Steel

- Heating Rate: 0-10℃/min

- Control System: PLC (Programmable Logic Controller)

The Sinter HIP Furnace is a high-pressure sintering furnace that is designed for high-temperature and high-pressure heat treatment processes.

With a temperature range of 0-1700℃, this furnace is capable of performing various heat treatment processes, such as sintering, annealing, and brazing. It also has a heating rate of 0-10℃/min, allowing for precise control over the heating process.

The control system of the Sinter HIP Furnace is equipped with a PLC (Programmable Logic Controller), ensuring accurate and efficient control over the entire heat treatment process. This allows for easy operation and monitoring of the furnace, making it an ideal choice for industrial production.

The Sinter HIP Furnace is built with high-quality materials, including stainless steel and carbon steel, to ensure durability and reliability. Its advanced design and construction make it suitable for use in various industries, such as aerospace, automotive, and energy.

Overall, the Sinter HIP Furnace is a high-performance and versatile furnace that is essential for any high-temperature and high-pressure heat treatment processes. Its advanced features and robust design make it an ideal choice for industrial applications.

Features:

- Product Name: Sinter HIP Furnace

- Type: Vacuum Furnace

- Heating Zone: 1-4

- Heating Rate: 0-10℃/min

- Vacuum Level: 1Pa

- Temperature Range: 0-1700℃

- High-Pressure Heat Treatment Furnace

- Pressure-Sintering Furnace

- High-Temperature Furnace

Technical Parameters:

| Technical Parameters | Sinter HIP Furnace |

|---|

| Vacuum Level | 1Pa |

| Temperature Range | 0-1700℃ |

| Type | Vacuum Furnace |

| Product Name | Sinter HIP Furnace |

| Control System | PLC |

| Vacuum Pump | Backing Pump+Roots Pump |

| Chamber Size | Customized |

| Heating Zone | 1-4 |

| Heating Rate | 0-10℃/min |

| Material | Stainless Steel, Carbon Steel |

| Type | High-Pressure Sintering Furnace |

| Type | High-Temperature Furnace |

| Type | Sintering-Process Furnace |

Applications:

Sinter HIP Furnace - Ruideer

The Sinter HIP Furnace, manufactured by Ruideer, is a state-of-the-art high-pressure sintering furnace designed for use in various industries such as powder metallurgy, ceramic materials, and aerospace industry. With its advanced technology and superior quality, it has become a highly sought-after product in the market.

Product Attributes:

- Brand Name: Ruideer

- Model Number: 10bar, 50bar, 98bar

- Place of Origin: China

- Certification: CE, TSG

- Minimum Order Quantity: 1 set

- Packaging Details: Wooden case

- Delivery Time: 5-6 months

- Payment Terms: T/T

- Control System: PLC

- Power Supply: 380V/50Hz

- Heating Element: Graphite

- Temperature Range: 0-1700℃

Application:

The Sinter HIP Furnace is primarily used for high-pressure sintering of various materials, including metals, ceramics, and composites. It is an essential equipment for powder metallurgy and is widely used in industries such as automotive, aerospace, and medical. The furnace is also suitable for sintering of advanced ceramic materials, such as zirconia and silicon nitride, which require high temperatures and pressures for their production.

Scene:

The Sinter HIP Furnace is an integral part of the sintering-process in various industries. In the automotive sector, it is used for the production of engine components, gears, and bearings. In the aerospace industry, it is utilized for manufacturing aircraft engine components, rocket nozzles, and turbine blades. In the medical field, it is used for the production of surgical implants and tools. The furnace can also be found in research institutions and universities for material development and testing.

Advantages:

The Sinter HIP Furnace boasts several advantages that make it the preferred choice in the market. Firstly, it has a high-pressure capability of up to 98bar, allowing for the production of high-density products with improved mechanical strength. Secondly, its temperature range of 0-1700℃ ensures precise control over the sintering process, resulting in uniform and high-quality products. Thirdly, the furnace is equipped with a PLC control system, which enables easy operation and monitoring of the sintering process. Lastly, the use of graphite as the heating element ensures excellent thermal conductivity and durability.

At Ruideer, we understand the unique needs of our customers. That's why we offer customized service for our Sinter HIP Furnace to meet your specific requirements. We take pride in providing high-quality and reliable performance in all of our furnaces, and our team of experts will work with you to create a customized solution that fits your needs.

Key Features

- High-pressure sintering process

- High-temperature furnace

- Vacuum furnace

- Customized service

- High-quality and reliable performance

Heating Element

This Sinter HIP Furnace is equipped with a heating element made of graphite, ensuring efficient and consistent heating for the sintering process.

Packing and Shipping:

Package and Shipping for Sinter HIP Furnace

The Sinter HIP Furnace will be carefully packaged and shipped to ensure its safe arrival to the customer. The packaging will be designed to protect the furnace from any damage during transportation.

Packaging:

- The furnace will be securely packed in a sturdy wooden crate.

- All fragile components will be wrapped in bubble wrap or foam for extra protection.

- The crate will be sealed and labeled with the necessary shipping information.

Shipping:

The furnace will be shipped using a reliable and reputable shipping company, chosen based on the customer's location and shipping preferences.

The shipping cost will be calculated and included in the final price of the furnace.

Once the furnace is shipped, the customer will receive a tracking number to monitor the status of their delivery.

Our team will also provide necessary documents for customs clearance if required.

We guarantee that the Sinter HIP Furnace will arrive at its destination in perfect condition.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is Ruideer. - Q: What are the different models available for this product?

A: The available models for this product are 10bar, 50bar, and 98bar. - Q: Where is this product manufactured?

A: This product is manufactured in China. - Q: What certifications does this product have?

A: This product is certified with CE and TSG. - Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1 set. - Q: How is this product packaged?

A: This product is packaged in a wooden case. - Q: What is the estimated delivery time for this product?

A: The estimated delivery time for this product is 5-6 months. - Q: What are the payment terms for this product?

A: The payment terms for this product are T/T (Telegraphic Transfer).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!