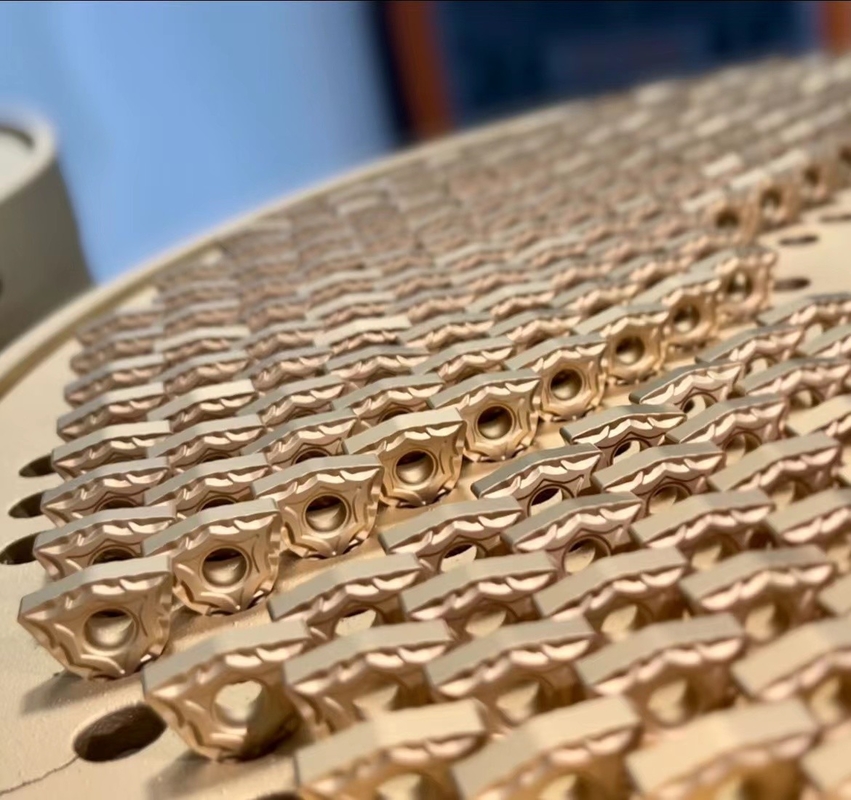

CVD Coating Furnace For CNC Carbide Tools Coating Service With Gold Black Layer

1. Assembly Group

The CVD coating furnace consists of six parts: workbench, reaction chamber, heating cover, cooling cover, rail crane, condenser.

The major systems are cooling water system, pump system, gas tube&pipeline system, aerodynamic system and electrical control system.

2. Factory working environment

2.1 Ambient humidity and temperature

2.1.1 Ambient humidity: <90% (at +35°C)

2.1.2 Ambient temperature: 5℃~40℃

2.2 Power supply

2.2.1 Power supply: 380V±10%, 50Hz, three-phase five-wire system

2.2.2 Control power supply: 210V~250V, 50Hz, single phase

2.3 Air source

2.3.1 Compressed air pressure: 6-7bar,

2.3.2 Ar pressure: 2-3bar,

2.3.3 H2 pressure and flow: 2-3bar, 0-75slm

2.3.4 N2 pressure and flow: 2-3bar, 0-50slm

2.3.5 CO pressure and flow: 2-3bar, 0-2.5slm

2.3.6 CO2 pressure and flow: 2-3bar, 0-5slm

2.3.7 CH4 pressure and flow: 2-3bar, 0-5slm

2.3.8 HCl pressure and flow: 2-3bar, 0-5slm

2.3.9 H2S pressure and flow: 2-3bar, 0-0.4slm

2.4 Water source

2.4.1 Cooling water inlet pressure: 2-3bar, pure water is recommended. The temperature is 13-16°C. (Customers need to be equipped with chilled water), cooling water flow, 5m3/h.

2.4.2 Emergency standby water source (to be prepared by the user)

Pressure: 1.5bar—2bar.

3. Equipment Strengths

1. Small floor space and reasonable layout.

2. High degree of automation.

3.Supporting auxiliary equipment such as tail gas neutralization device, titanium tetrachloride filling device, gas busbar, etc., can be provided.

4. Process control system is conducive to independent R&D of new processes

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!