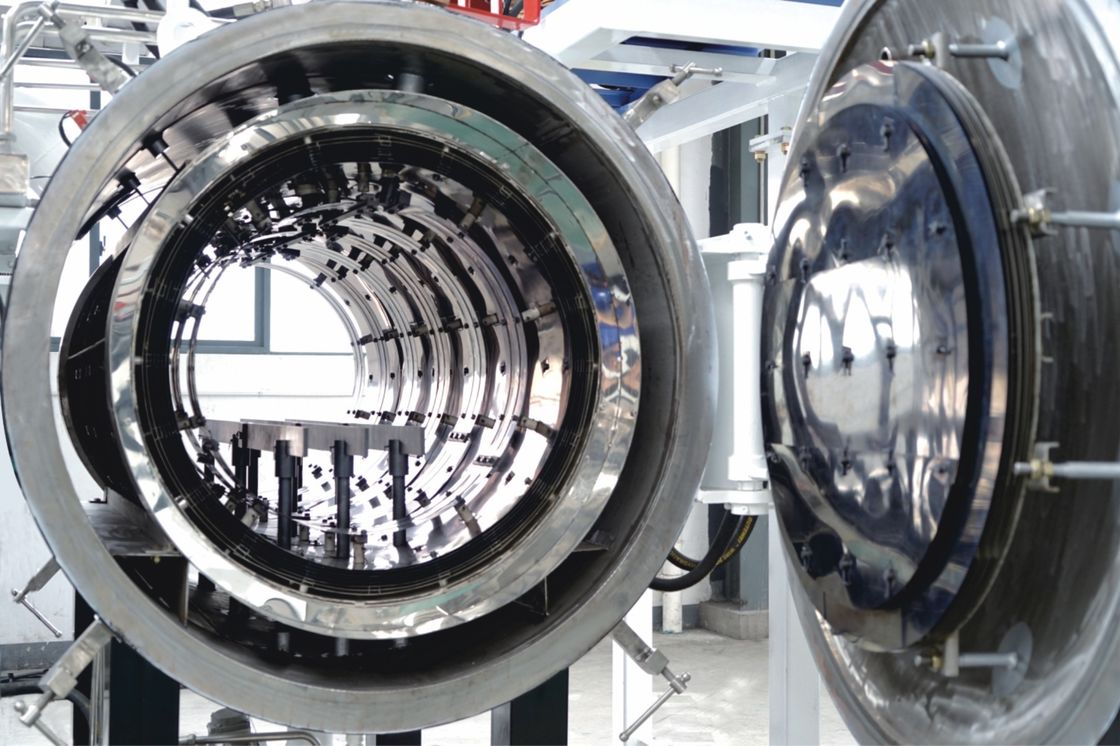

220KVA Metal Sintering Furnace With Molybdenum Heating Element

300*300*900 Metal Sintering Furnace adopts molybdenum as heating element

Design Standards

This metal vacuum sintering furnace features a single chamber, double door horizontal periodic heating structure designed for easy handling and maintenance. The entire process is automatically controlled, enabling full load continuous operation with capacity for 300 furnace cycles or 300 working days per year.

The system utilizes graphite element resistance heating (low voltage, high current) with multiple heating units, each independently temperature-controlled. Equipped with fully automatic control and safety interlock functions, the entire process is computer-controlled with real-time monitoring, tracking, and recording of temperature, pressure, vacuum parameters, and alarm interlocking for reliable safety.

Technical Parameters

| Effective Working Zone Size (W*H*L) |

300mm * 300mm * 900mm |

| Maximum Loading Capacity |

100kg (depends on product type) |

| Working Temperature |

1200℃ (maximum design temperature)

1150℃ (actual working temperature) |

| Pumping Speed |

Vacuum reaches 5Pa within 30min after pump start

Limit vacuum reaches 1Pa after 30min pumping from 5Pa

After drying furnace, under empty furnace, clean and cold state |

| Leakage Rate |

≤3Pa/h

Measuring limit vacuum after drying furnace, average within 3 hours in empty furnace, clean and cold state |

| Cooling Mode |

Internal rapid cooling fan with water cooling system |

| Heating Zone Quantity |

2 or 3 zone independent temperature control |

| Temperature Control Mode |

PID adjustment |

| Heating Power |

Approximately 220KVA |

| Uninterrupted Power Supply |

Powers indicator lights and furnace control during outages

Duration: ≥80 minutes |

Equipment Functions

- Automatic leak detection function

- Ar negative pressure debinding function

- H2 micro-positive pressure debinding function

- Vacuum sintering function

- Ar partial pressure sintering function (dynamic and static partial pressure)

- Vacuum cooling function

- Electrified cooling and thermal insulation function

- Rapid cooling function (internal heat exchanger)

- Fully automatic control function

- Safety interlock function

- Break point reheating function

- Wireless remote diagnosis function

Equipment Systems

Includes control system, heating system, positive and negative pressure vacuum system, cooling water system, rapid cooling system, safety system, and auxiliary system.

After-Sales Service

Installation, Commissioning and Acceptance

We provide installation, commissioning, and acceptance services at buyer's plant. Equipment inspection includes verification of all components, accessories, spare parts, special tools, manuals, and technical documents according to packing list.

Training

Comprehensive staff training covering practical operation, maintenance procedures, basic principles, equipment maintenance knowledge, and common fault handling measures. We train 2-3 workers in maintenance and operating procedures.

Warranty Period

12-month warranty period starting from installation and debugging date. Technical support provided within 2 hours of notification, with on-site service personnel arriving within 48 hours when required.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!