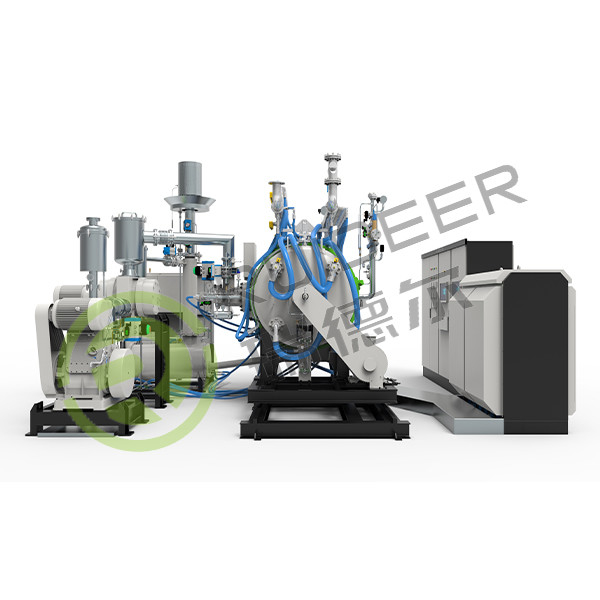

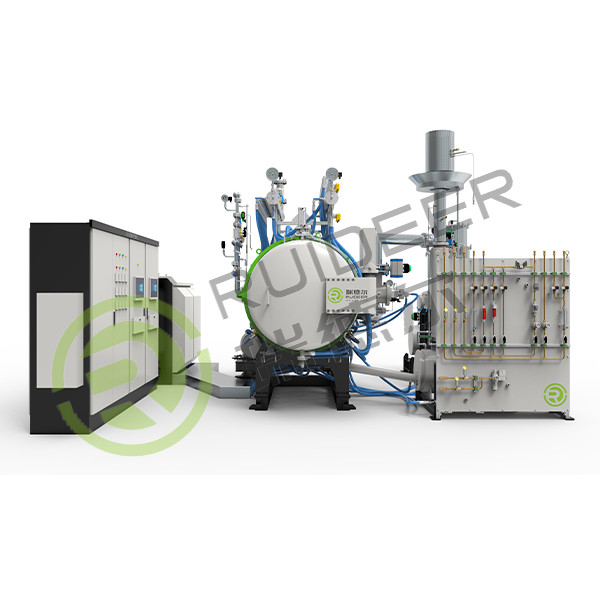

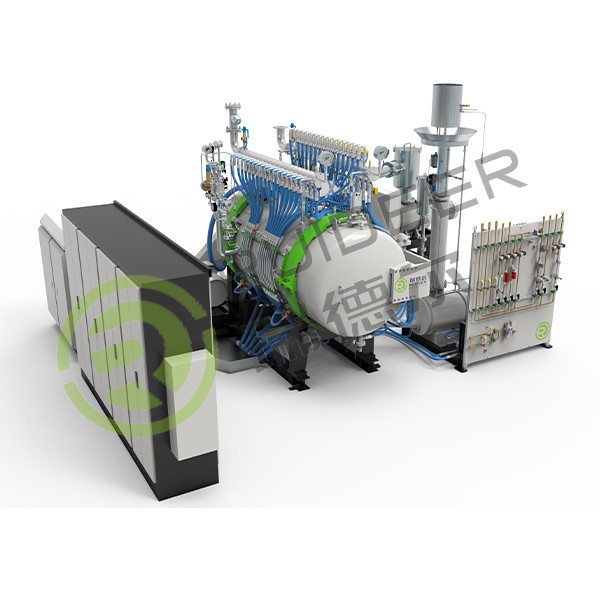

China 10mpa horizontal vacuum rapid cooling sinter HIP furnace

Features:

- Secially Designed for Rapid Cooling

This furnace can rapidly cool objects from high temperatures, thanks to a large internal fan that operates under high gas pressures and a water cooling system. This reduces cycle time and contributes to increased productivity.

- Performs Degassing, Dewaxing and Sintering in Sequence

Uses internal tight box to discharge binder vapors and prevent them from adhering to or contaminating furnace walls or the heat-insulating layer.

| Furnace Type |

Horizontal type(Max Working pressure:58bar/98bar |

| RDE-3312-N |

RDE-4412-N |

RDE-5512-N |

RDE-5518-N |

| Usable Space (W*H*L) |

300*300*1200mm |

400*400*1200mm |

500*500*1200mm |

500*500*1800mm |

| Max.Charge Load |

300kg |

500kg |

1200kg |

1500kg |

| Power Rating |

320KVA |

320KVA |

430KVA |

600KVA |

| Heating Zone |

2/3 Zones |

3 Zones |

3 Zones |

3 /4 Zones |

| Cooling time |

≤5h |

≤6h |

≤7h |

≤8h |

|

Empty furnace, cooling from sintering temperature 2100℃ to 100℃.

(water temperature≤26℃, water pressure 2-3bar, 55bar(95bar)≤Ar pressure≤58bar(98bar).

|

| Service Life |

20years/6000furnace cycles |

| Max. Working Temp |

1800℃ |

| Temperature Measurement |

Special design High temperature W-Re5/26 Thermocouple |

| Max Vacuum Degree |

1Pa (under cold, empty, dry furnace) |

| Leakage Rate |

3Pa/h (Average value under cold, empty, dry furnace) |

| Wax Collection |

≥98%(Argon gas negative dewaxing, 3-time average value) |

| Forming Agent |

Paraffin,PEG,Rubber,(C12H22O5)n etc. |

| Input gas |

N2, Ar, H2 |

| Functions |

Automatic Positive Pressure, Negative Pressure Leak Detection

Ar Negative Pressure Dewaxing/H2 Micro Positive Pressure Dewaxing

Vacuum Sintering

Partial Pressure Sintering (Static, Dynamic)

Pressure Sintering

Rapid Cooling

Fully-automatic control & Safety interlock& Breakpoint continuing heating & Wireless remote control& Self-diagnosis

|

How is the Rapid cooling system operating in sintering furnace?

The fast cooling of the pressurized sintering furnace is divided into two stages. The first stage is to cool down naturally under the pressure environment, and the heat preservation door is closed; the second stage is to open the heat preservation door after reaching the set temperature to make the high pressure in the furnace. The argon gas passes through the radiator on the furnace door to quickly take away heat. When the furnace top furnace temperature or the furnace door radiator temperature reaches the upper limit, the heat preservation door is closed again, and the furnace top furnace temperature or the furnace door radiator temperature drops accordingly. When the temperature of the top furnace or the radiator of the furnace door drops, when the temperature is lower, the insulation door is opened again. After several cycles, the temperature of the furnace top or the radiator of the furnace door no longer reaches the upper temperature limit, and the insulation door is always open.

• Design standards

The equipment is designed in accordance with the pressure vessel requirements of the Quality and Technical Supervision Bureau, and is qualified after pressure testing and shipped. The electrical design and construction meet national standards.

• Installation pre-test and pre-acceptance

The equipment is fully assembled in our factory, including all pipelines, vacuum pipelines, process gas pipelines, cooling water pipelines, compressed air pipelines, etc. Pre-testing can be carried out after installation. At the customer site, pipelines other than the equipment are provided by the customer. The installation also includes the connection of all cables. At the customer site, the main cable connecting the power cabinet is provided by the customer. After installation, we conduct vacuum and positive pressure leakage tests on the entire equipment, as well as mechanical and electrical function tests.

• Disassembly and transportation

The equipment will be disassembled in several large parts, packed in a standardized manner, and loaded into the transport vehicle.

• Customer site installation and commissioning

The Redel after-sales engineer will lead the team to complete commissioning, product trial burning and other work within 20 working days. The customer needs to make appropriate preparations and provide the necessary tools, such as hoisting and lifting equipment. And provide installation personnel support (it is recommended to have 1 mechanical personnel and 1 electrical personnel).

• Final acceptance

After installation and commissioning, the equipment can be finally accepted in accordance with the requirements of the technical contract.

• Training

Our after-sales engineers will provide a systematic and complete on-site training, including operation, maintenance, troubleshooting, etc.

• Technical data delivery

To ensure safe operation and equipment maintenance, the following technical data will be provided to customers:

1. Equipment installation layout

2. User manual

3. Spare parts list

4. Electrical drawings

5. Component manual

FAQ

Are you a factory or trading company?

Q: Are you a factory or trading company?

A:We are China leading high-temperature vacuum furnace manufacturer with over 10 years’ experience.

Do you have customization or OEM service?

Q: Do you have customization or OEM service??

A:Yes,we have powerful R&D team and high-tech equipment.So we can not only supply the regular model,but also the customizable furnace as the repuirment of our clients.

What's your advantage?

Q:What's your advantage?

A:

l Quick response to your enquiry

l High quality control

l Stable supply chain

l Timely delivery

l Excellent after-sales service

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!