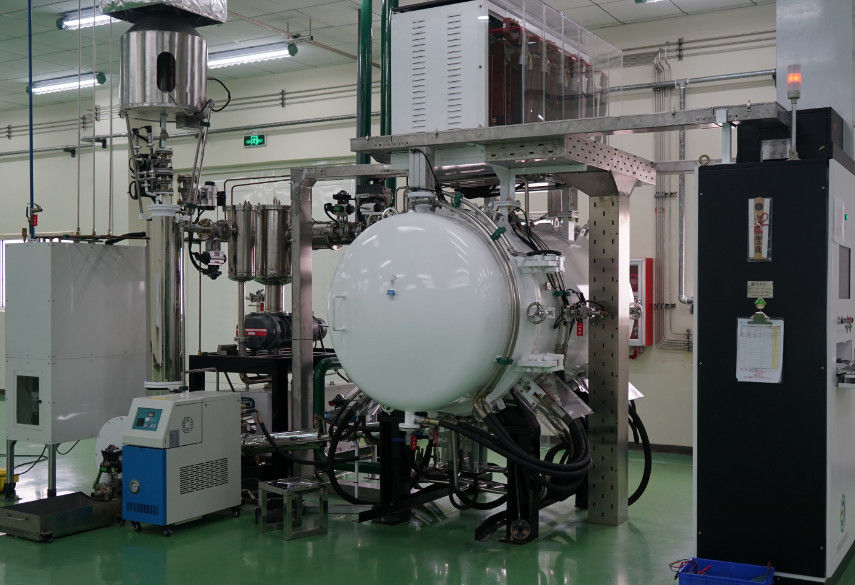

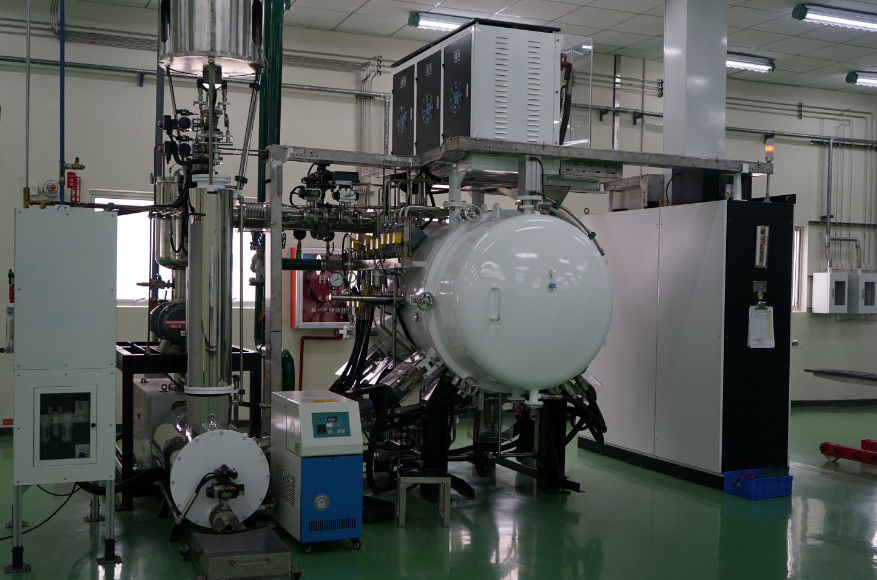

Metal Annealing Vacuum Furnace With Excellent Performance

The molybdenum-made sintering furnace is single-chamber, horizontal,and with internal circulation air cooling,which adopt low voltage and high current molybdenum heating element for periodic heating.In addition, there are multiple heating units, each of which controls the temperature separately. The equipment is used for vacuum and high temperature degassing sintering of high density alloys, tungsten-nickel alloys, tungsten-copper alloys, titanium alloys, magnetic materials, etc.It can also be applied to vacuum heat treatment process of other rare metal materials. The whole process is controlled by automatic and manual dual-mode control, monitoring, tracking, self-diagnosis simulation, display and recording.

It is mainly composed of furnace body (shell, door, door clamping mechanism, furnace door supporting hinge, heating body, heat insulation screen, charging platform, etc.), vacuum system, water cooling system, pneumatic system, rapid cooling system, charging and discharging system, PLC program control, electrical control cabinet, etc.

PLC, industrial control computer (IPC) control to achieve the whole process of one-click start, real-time dynamic monitoring.The computer saves temperature, pressure, vacuum and other parameters.It also has afe and reliable alarm interlock.

It also equipped with different system function, such as control system, heating system, vacuum system, ventilated system, partial pressure sintering system,cooling water system, rapid cooling system and electrical control system. Different systems plays important roles to make the dfurnace has great performance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!