High temperature vacuum sintering furnace (for non-metal ceramic and Sic carbide,it also can be customized)

High temperature vacuum furnace

Structure characteristics high temperature vacuum furnace:

1.The structure of the furnace is horizontal before and after the fast door structure, fine workmanship, beautiful appearance.

2. The furnace shell is designed with double-layer clamped wall water-cooled structure. The inner layer is made of high-quality stainless steel.The outer material and flange of the furnace shell are made of Q235A. All the metal structural parts and peripheral water pipes in the furnace are made of stainless steel.

3. H-150a mechanical pump + zjy-600a roots pump unit is adopted in the vacuum acquisition system.

4. In order to prevent pollution to the pump group, a dust filter device is installed in front of the pump group;Considering the need of powder treatment process, the vacuum acquisition system designed a throttle and slow suction branch for the initial stage of vacuum pumping to avoid the occurrence of "dust" phenomenon.

5. The heat insulation box is made of 120mm thick graphite board lined with 20mm heat insulation layer, and the outer layer is made of 20mm hard carbon felt to ensure high working temperature and low energy consumption.

6. Graphite track is installed to facilitate product loading and unloading, and a dedicated simple product loading and unloading truck is equipped (fixed height, manual driving, electric feeding and discharging).

7. Special high-temperature ceramic insulation parts and structural parts are used in high temperature areas.

8. When the temperature is lower than 1600℃, the thermocouple is used to automatically monitor the temperature, and an interface is reserved for the optical pyrometer to monitor the temperature when the temperature is higher than 1500℃.

9. In order to prevent the failure of abnormal temperature such as overtemperature of the equipment and to confirm the accuracy of temperature in the high-temperature sintering process, a thermocouple is specially installed for temperature comparison.

10. Adopt internal circulation rapid cooling mode with argon as the cooling medium;Water - cooled sealed motor has high sealing reliability.

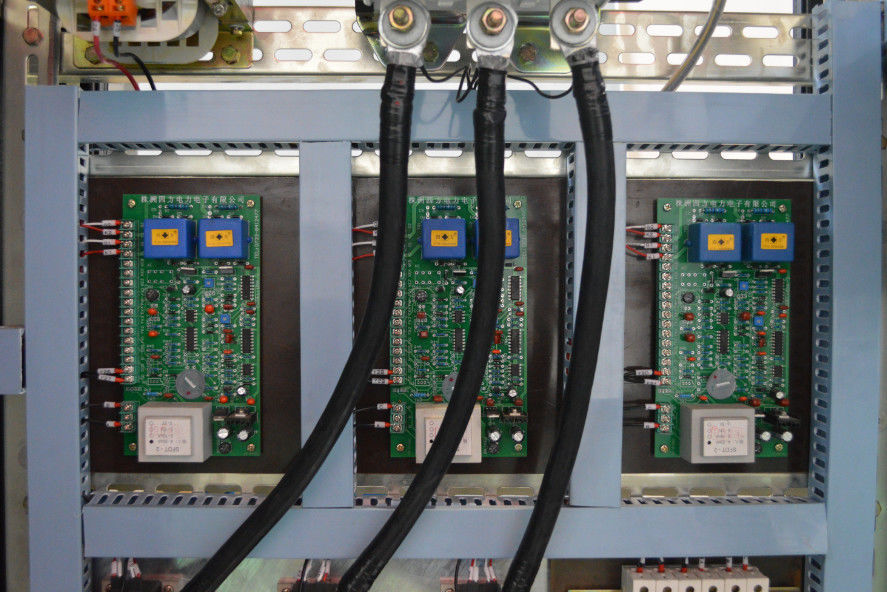

11. The temperature is automatically controlled by a temperature control instrument, and other operations such as valve and switch are manually operated.

12. The equipment has the basic safety protection function and the alarm function of overtemperature and water cut-off.The electric appliance is equipped with the protection of overheating, short circuit and electricity leakage.

Equipment parameters:

| Valid capacity |

500*500*1800 |

| Max.temperature |

1800℃ |

| Cooling time |

≤10h-14h

|

| Ultimate vacuum degree |

3.0×10-3Pa |

| Vacuum leakage rate |

3Pa/h |

| Vacuum pump |

slide valve pump,roots pump,oil diffusion pump |

| Temperature and atmosphere uniformity |

temperature difference≦±7℃ |

| Temperature measure mode |

WRe5-26thermocouple |

| Temperature control mode |

3 zone temperature control |

| Function |

Vacuum sintering,atmosphere sintering,rapid cooling |

| Heating power |

320KVA |

After sales:

1.Installation, Commissioning And Acceptance

We do installation, commissioning and acceptance in buyer's plant.During the installation and commissioning period, the commissioning personnel shall be provided free of charge by the demander according to the staff standard.

The equipment shipped to the buyer, the seller received the buyer's notification, both within a week to carry the equipment out of the box together, then check the equipment and all components according to the packing list . Including equipment accessories, spare parts and special tools, attached manual and technical documents, etc. It can be installed after the acceptance check of equipment.

After installation and debugging, the equipment shall be accepted according to the technical accessories.

2.Training

When taking-over the Furnace to the customer, We will give a staff training to customer. The operating personnel of the customer should join to commission,test the furnace, when installing at customer’s company.

This is practical operation training and practical maintenance training,

and our technical personnel will telling the basic principle,equipment maintenance knowledge,And the common fault handling measures.We can training 2 ~ 3 workers. ( Training how to maintenance and operating.)

3. Warranty period

The warranty period of the equipment is 12 months, which starts from the date of installation and debugging of the supplier. Equipment failure happens, after-sales service personnel shall give solutions within 2 hours, after receiving the buyer's notification . If it is need to go to the site for treatment , operators dispatched by seller should arrive at the site within 48 hours after go aboard. In case of emergency,operators should arrive at the site within 48 hours after go aboard, and continue to make repairs until the fault is removed and the equipment returns to normal.

Note:

We are a professional manufacturer of powder metallurgy sintering furnaces. Custom design is available according to customer’s requirements. Please offer us the sintered material, size of sintered piece, max. temperature, heating zone dimensions, vacuum level and other special requirements when making inquiries. We will offer professional proposal and solutions based on your requirements.

Quality assurance and service:

1. Our company guarantees that all materials and purchased components meet the national technical quality standards.

2. Within one year from the date of acceptance of the equipment, if there is any quality problem caused by the design or manufacture of the equipment, our company will carry out free maintenance and bear the maintenance cost.If the equipment exceeds the warranty period or is damaged due to human error or force majeure (such as natural disaster), our company will actively provide high-quality paid service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!