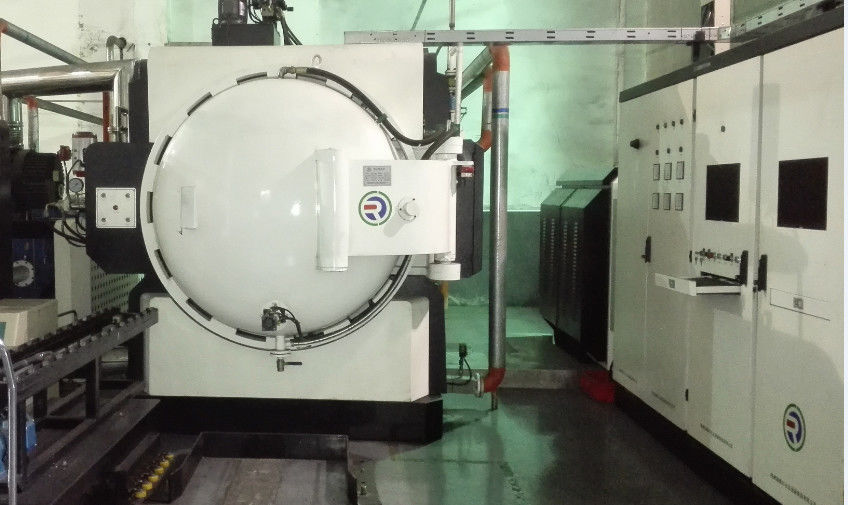

Vacuum heat treatment sintering furnace(directional appliance,intensive development,built for professionals)

Design description:

The heat treatment sintering furnace is a single chamber and double door horizontal and periodic heating structure,which is designed for easy handling and maintenance, the whole process is controlled automatically.It can realize full load continuous operation, 300 furnace times/year or 300 working days/year.It uses graphite element resistance heating (low voltage, high current) .In addition, there are multiple heating units, each of which controls the temperature separately.It equipped with fully automatic control function and safety interlock function.The whole process is automatically controlled, monitored, tracked and recorded by computer.The PLC, industrial computer (PC) control to realize the whole process of one-key start, real-time dynamic monitoring, computer will save temperature, pressure, vacuum and other parameters ,alarm interlocking is safe and reliable.

Working environment of plant

Humidity and temperature requirement

3.1.1 Environment humidity: <90%(at 35℃)

3.1.2 Environment temperature: -10℃~+40℃

3.2 Power supply

Main technical parameters:

|

Service life of furnace shell

|

20 years

|

|

Furnace shell working time

|

6000 (furnace/time)

|

|

Effective working zone size(W*H*L)

|

300mm×300mm×1000mm |

|

Max loading capacity

|

(it depends on the type of product) |

|

Working temperature

|

1300℃(The maximum design temperature) |

| |

1250℃(The actual working temperature) |

|

Pumping speed

|

The vacuum degree can reach 5Pa within 30min after the pump is started, and the limit vacuum value can reach 1Pa after pumping for 30min after reaching 5Pa

(After drying the furnace,under the empty furnace, clean and cold state)

|

|

Leakage rate

|

≤3Pa/h

(Measuring the limit vacuum after drying the furnace, stop the operation of the pump group and start the test.Average within 3 hours in empty furnace, clean and cold state)

|

|

Cooling speed

|

The furnace is empty.From 1450℃ cooling to 100℃ will cost less than and equal to 6 hours.(Water temperature≤28℃,2bar≤Water pressure≤3bar)

|

|

Cooling mode

|

The inner furnace is equipped with rapid cooling fan and water cooling will cooling with the furnace.

|

After sales:

1.Installation, Commissioning And Acceptance

We do installation, commissioning and acceptance in buyer's plant.During the installation and commissioning period, the commissioning personnel shall be provided free of charge by the demander according to the staff standard.

The equipment shipped to the buyer, the seller received the buyer's notification, both within a week to carry the equipment out of the box together, then check the equipment and all components according to the packing list . Including equipment accessories, spare parts and special tools, attached manual and technical documents, etc. It can be installed after the acceptance check of equipment.

After installation and debugging, the equipment shall be accepted according to the technical accessories.

2.Training

When taking-over the Furnace to the customer, We will give a staff training to customer. The operating personnel of the customer should join to commission,test the furnace, when installing at customer’s company.

This is practical operation training and practical maintenance training,

and our technical personnel will telling the basic principle,equipment maintenance knowledge,And the common fault handling measures.We can training 2 ~ 3 workers. ( Training how to maintenance and operating.)

3. warranty period

The warranty period of the equipment is 12 months, which starts from the date of installation and debugging of the supplier. Equipment failure happens, after-sales service personnel shall give solutions within 2 hours, after receiving the buyer's notification . If it is need to go to the site for treatment , operators dispatched by seller should arrive at the site within 48 hours after go aboard. In case of emergency,operators should arrive at the site within 48 hours after go aboard, and continue to make repairs until the fault is removed and the equipment returns to normal.

Note:

We are a professional manufacturer of powder metallurgy sintering furnaces. Custom design is available according to customer’s requirements. Please offer us the sintered material, size of sintered piece, max. temperature, heating zone dimensions, vacuum level and other special requirements when making inquiries. We will offer professional proposal and solutions based on your requirements.

Quality assurance and service:

1. Our company guarantees that all materials and purchased components meet the national technical quality standards.

2. Within one year from the date of acceptance of the equipment, if there is any quality problem caused by the design or manufacture of the equipment, our company will carry out free maintenance and bear the maintenance cost.If the equipment exceeds the warranty period or is damaged due to human error or force majeure (such as natural disaster), our company will actively provide high-quality paid service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!