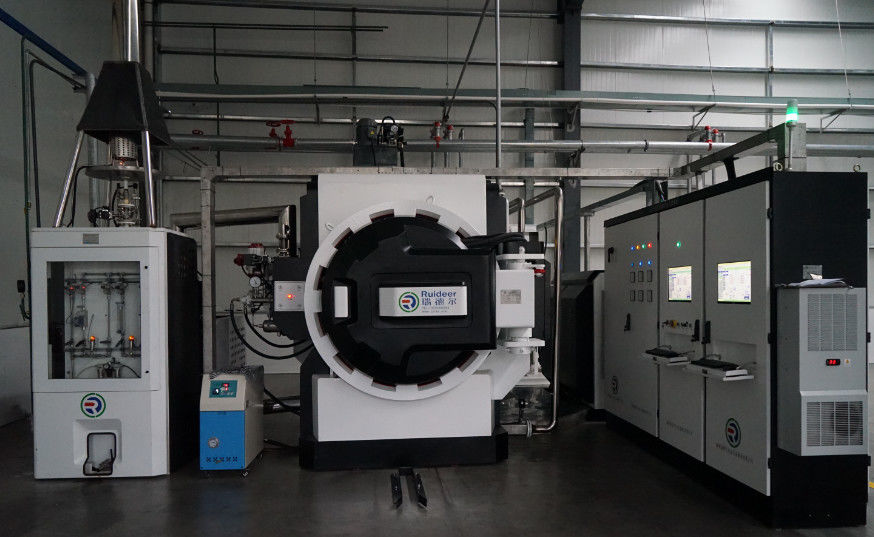

Return Permeability Ceramic Sintering Furnace / Industrial Vacuum Sintering Furnace

Equipment description:

On the whole, it meets the strict requirements of temperature uniformity and atmosphere uniformity in powder metallurgy.The furnace structure design is advanced and reasonable, which is convenient for operation and maintenance.The main supporting components (sensors, graphite heating element, thermocouple, main control valve, vacuum pump, etc.) have the international advanced level and can adapt to the long-term, stable and reliable mass production requirements.At the same time, the equipment should also meet the national requirements for energy conservation and environmental protection.

Equipment function:

Realize the function of vacuum sintering and rapid cooling;The whole process of manual button operation, temperature control using Yokogawa-550 instrument temperature control.

Working environment of plant:

Humidity and temperature requirement

Environment humidity: <90%(at +35℃)

Environment temperature: -10℃~45℃

Power supply

Motive power supply: 375V--430V,50Hz,3 phase 5 wire system;Heating power:600KVA

Control power supply(China standard): 210V~250V,50Hz,Single-phase

Water:Totally enclosed circulating water

Gas:

Process gas:Ar,N2

Compressed air pressure: 0.6MPa ~0.8MPa

Technical paremeter table

| Design run times |

300 furnace/year |

| Valid working zone size |

500mm×500mm×1500 mm (W×H×L) |

| Max.loading capacity |

≥1000Kg(It depends on the product type) |

| Max.working temperature |

1400℃ |

| Pumping speed |

The vacuum degree can reach 5Pa, and then pump within 30min after reaching 5Pa. The ultimate vacuum value should reach 1Pa (in the case of cold, air and dry after heating up furnace). |

| Leakage rate |

≤2Pa/h(after testing the limit vacuum, empty furnace, clean and cold state,average value winthin 12 hours) |

| Max.positive pressure |

10KPa |

| Rapid cooling time≤8h |

|

| Max.heating up speed(full loading) |

≥6℃/min |

| Heating power |

proximately 220KW |

| Loading plate size |

720*480*35mm(2 plate) |

After sales:

1.Installation, Commissioning And Acceptance

We do installation, commissioning and acceptance in buyer's plant.During the installation and commissioning period, the commissioning personnel shall be provided free of charge by the demander according to the staff standard.

The equipment shipped to the buyer, the seller received the buyer's notification, both within a week to carry the equipment out of the box together, then check the equipment and all components according to the packing list . Including equipment accessories, spare parts and special tools, attached manual and technical documents, etc. It can be installed after the acceptance check of equipment.

After installation and debugging, the equipment shall be accepted according to the technical accessories.

2.Training

When taking-over the Furnace to the customer, We will give a staff training to customer. The operating personnel of the customer should join to commission,test the furnace, when installing at customer’s company.

This is practical operation training and practical maintenance training,

and our technical personnel will telling the basic principle,equipment maintenance knowledge,And the common fault handling measures.We can training 2 ~ 3 workers. ( Training how to maintenance and operating.)

3. warranty period

The warranty period of the equipment is 12 months, which starts from the date of installation and debugging of the supplier. Equipment failure happens, after-sales service personnel shall give solutions within 2 hours, after receiving the buyer's notification . If it is need to go to the site for treatment , operators dispatched by seller should arrive at the site within 48 hours after go aboard. In case of emergency,operators should arrive at the site within 48 hours after go aboard, and continue to make repairs until the fault is removed and the equipment returns to normal.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!