Professional Ceramic Sintering Furnace Temperature Control Mode 3 Zone Maximum Load 1800Kg

Description:

The ceramic sintering furnace is single-chamber, horizontal and periodic heating. It adopt low voltage and large current graphite heating element to heating, and it has multiple heating units, each unit controls the temperature separately. The whole process is automatically controlled, monitored, tracked and displayed and recorded by the computer.

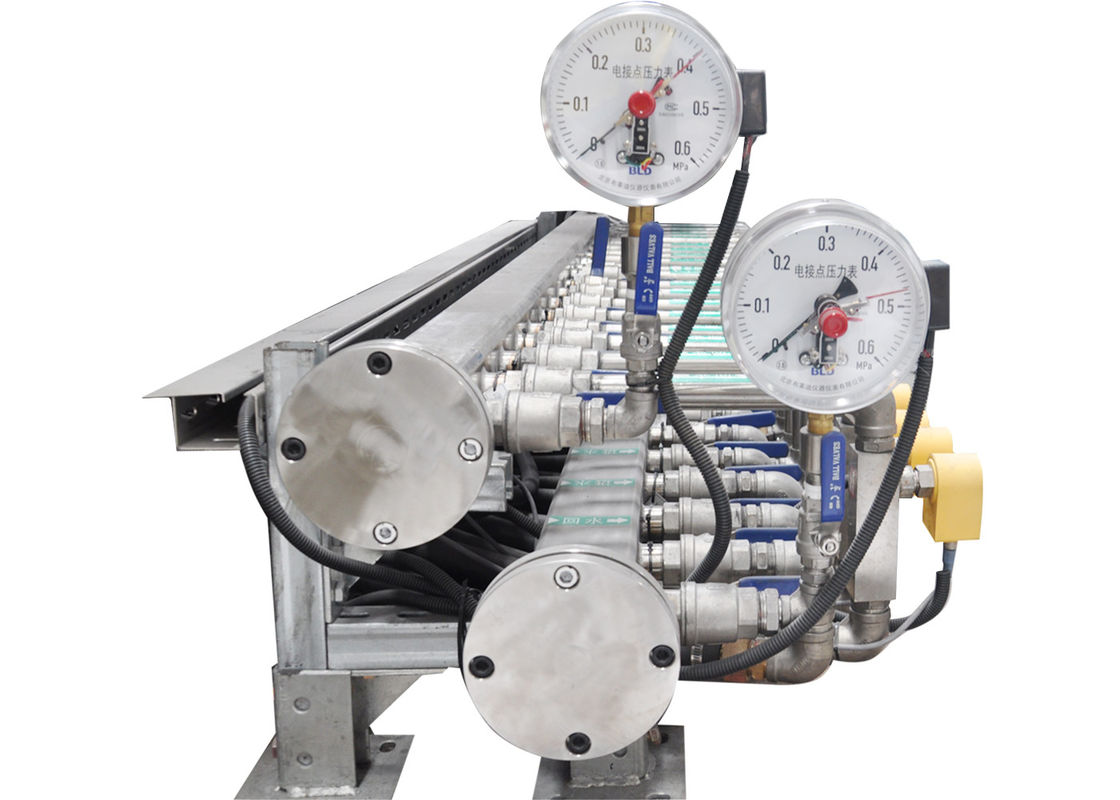

It including control system, heating system, vacuum system ,cooling water system, rapid cooling system, auxiliary system and safety system.

It adopt the structure of built-in graphite liner in insulation

tube. In general, it meets the strict requirements of temperature uniformity and atmosphere uniformity in the sintering process of high-performance materials. The furnace structure design is advanced and reasonable, and it is easy to use and maintain.

Vacuum pump: backing pump,Roots-type pump(slide valve pump, rotary vane pump, screw pump and so on can be selected for the backing pump, allowing customers to choose world-class brand products)

Power supply: General standard is three phase five wire system AC380V±10% 50HZ.

Control power supply:Single-phase AC210V-250V 50HZ design(Different countries and regions can be designed according to local grid standards)

Temperature measurement mode ;:WRe5-26 thermocouple

Technical parameters:

| Item |

Content |

|

MAX working pressure

|

100KPa |

|

Cooling periodSintering temperature—100℃

|

480min |

|

Temperature control mode

|

3-zone

|

|

Functions:

|

vacuum heating,heating flowing gas,Rapid cooling. |

Applications: For Non-metal ceramic, Precision Ceramic, Life ceramics, Industrial ceramics, Sic carbide

Experience Advantages

1. We have been engaged in designing and manufacturing furnaces for more than 15 years.

2. Commissioning experience of hundreds of gas pressure sintering furnaces.

3. We have a professional team that is capable of completing installation and commissioning within 25 days if water, electric and gas are ensured.

After-sales service

1. We provide technical support and professional solutions according to your production process.

2. We will be responsible for the liability related to intellectual property rights arising from or in connection with the design, manufacturing, sales and operation of the vacuum-pressure sintering furnace. Customers will not be responsible for such liability.

3. We offer 12-month warranty for this gas pressure sintering furnace. If equipment failure happens, our after-seals personnel will respond within 24 hour after being notified, and if on-site assistance is required, our personnel will arrive at the site within 48 hours. They will check and repair the equipment until it works normal again.

4. If any loss or damage arises during the warranty period from equipment quality, we will offer free replacement or repair. If it’s not due to quality, or it’s caused by customer’s negligence or improper operation, customer can contact us for paid technical assistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!