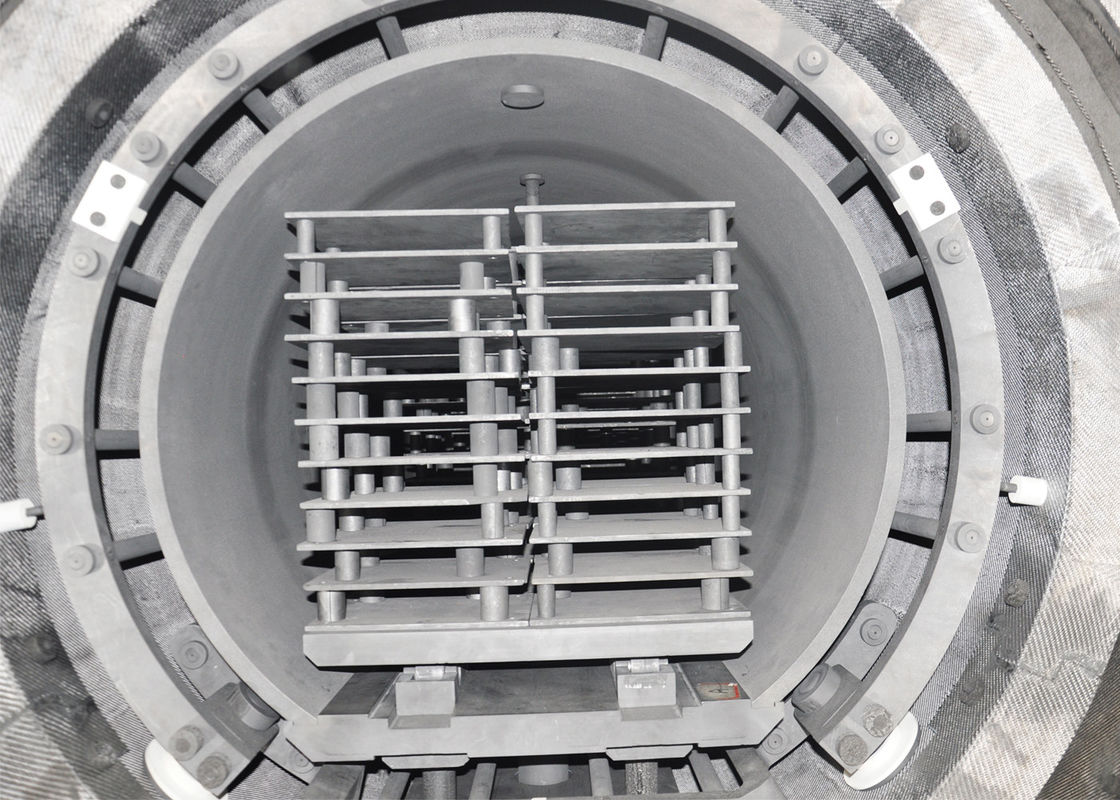

Large Capacity High Pressure Furnace , Metal Sintering Furnace Heating Evenly

Description:

High Pressure Sintering Furnaces is beneficial to increase the sintering density of the material and improve the mechanical properties of the material. The pressure sintering furnace has excellent structure, strength and density. Can be achieved continuous differential pressure degreasing, vacuum sintering and pressure sintering process; with atmosphere regulation function, the furnace stability, product quality easy to control; furnace partial pressure control, to achieve constant pressure sintering.

High Pressure Sintering Furnaces Features:

1, high production efficiency, less decarbonization, saving materials and forging die costs.

2, heating evenly, the table temperature difference is very small, high temperature control accuracy

3, the working environment is superior, improve the workers working environment and corporate image, pollution-free, low energy consumption.

Technical parameters:

|

Specifications

|

RDE-DYL-224 |

RDE-DYL-336/RDE-DYL-339 |

RDE-DYL-3535120/RDE-DYL-4412 |

RDE-DYL-5512/RDE-DYL-5518 |

RDE-DYL-5527 |

|

Effective space(w* h * l)mm

|

200*200*400 |

300*300*600/

300*300*900

|

350*350*1200/

400*400*1200

|

500*500*1200/

500*500*1800

|

500*500*2700 |

|

Max.Temperature

|

1600℃ |

1600℃ |

1600℃ |

1600℃ |

1600℃ |

| Maximum load |

50Kg |

150Kg/200Kg |

300Kg/350Kg |

1200Kg/1500Kg |

2000Kg |

|

Vacuum leakage rate:(Average in cold,empty,dry chamber in 3 hours)

|

1Pa/h |

2Pa/h |

2Pa/h |

3Pa/h |

3Pa/h |

| Extreme vacuum |

0.8Pa |

0.8Pa |

0.8Pa |

1Pa |

1.5Pa |

| Wax-collection rate(negative pressure dewaxing process.The maximum average value is 3 furnaces) |

98% |

98% |

98% |

98% |

98% |

|

Working pressure

|

1MPa/2MPa/

6MPa/10MPa

|

1MPa/2MPa/

6MPa/10MPa

|

1MPa/2MPa/

6MPa/10MPa

|

1MPa/2MPa/

6MPa/10MPa

|

1MPa/2MPa/

6MPa/10MPa

|

|

Cooling period(Sintering temperature—100℃)

|

40min-120min |

40min-150min |

120min-360min |

180min-420min |

180min-480min |

|

Temperature control mode

|

Single zone/2-zone

|

2-zone/3-zone

|

2-zone/3-zone

|

3-zone/4-zone

|

4-zone

|

| Atmosphere and temperatureuniformity |

Com≤±0.15%

Hc≤±0.25KA/M

|

Com≤±0.15%

Hc≤±0.25KA/M

|

Com≤±0.2%

Hc≤±0.3KA/M

|

Com≤±0.2%

Hc≤±0.3KA/M

|

Com≤±0.2%

Hc≤±0.3KA/M

|

|

Input gas allowed

|

Ar,N2,He,H2,CH4,Co2 |

|

Functions:Vacuun dewaxing,H2 dewaxing,vacuum heating,heating with gas mixture(Co2 /CH4/H2),heating flowing gas,heating pressure gas,Rapid cooling.

|

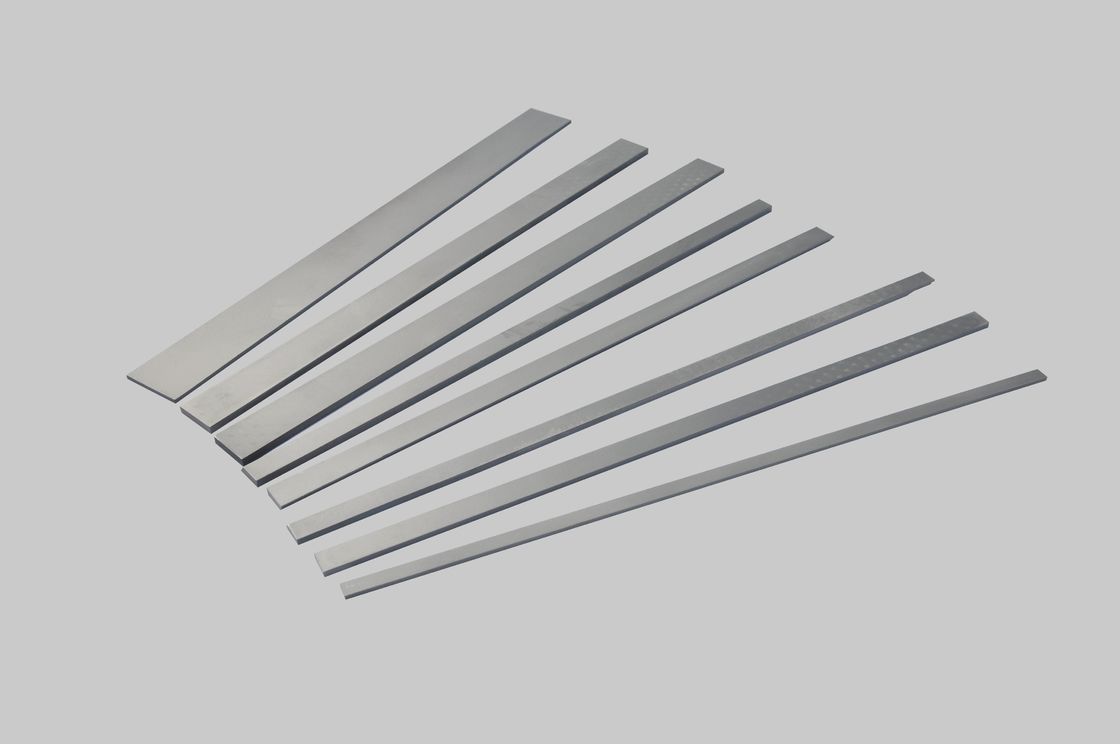

Applications:For Cemented Carbide , Precision Ceramic , stainless steel , Iron-bae alloy , Copper-base alloy , Aluminum products

Installation of High Pressure Sintering Furnaces:

l, check the control cabinet all parts and accessories are complete, intact.

2, the cabinet installed in the corresponding foundation, and fixed.

3, according to the wiring diagram, and refer to the electrical schematic diagram, connected to the external main circuit and control loop, and reliable grounding, to ensure correct wiring.

4, check the movable part of the electrical activities should be free, no stuck phenomenon.

5, the insulation resistance should be no less than 2 megohms.

6, vacuum furnace The valve must be in the closed position.

7, control the power switch on the switch.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!